Development of energy capture system from vibrations for vibration motion sensors

Project Description: For various industry sectors today, predictive maintenance has become recognized as the best maintenance strategy. Industries with high-cost machines or that need to run for long periods without downs, are examples of sectors where predictive maintenance is essential. Thus, the health of a machine is commonly monitored with vibration sensors to predict possible failures and define where they can occur. These sensors should have great autonomy, be compact and preferably wireless. Because in this way, the operator can perform readings remotely, install them easily in places with limited space and keep the sensor in place for long periods of time without having to spend resources on multiple installations. Electrical devices like these have experienced a great technological advance that has caused a rapid reduction in their electrical consumption. This reduction allowed various forms of energy capture from the environment to replace or complement traditional batteries. These energy capture devices or Energy Harvester (EH) can make use of various forms of energy that are available in the environment, such as solar, thermal, chemical and mechanical energy. The latter has the advantage of being sustainable, stable and small, besides being able to capture energy from various sources such as industry machinery and equipment, vehicles, human movement and fluids. This project aims to investigate EHs alternatives for capturing energy from vibrations as a way to increase the life of sensors for monitoring vibrations used in predictive maintenance processes.

Coordinator/ Participants: Prof. Júlio Apolinário Cordioli (coordinator); Guilherme Cartagena Mirón (participant/ LVA UFSC); Airton José Schmidt Júnior (participant LVA/UFSC); Gabriel Rogério da Silva (participant/ LVA UFSC); Danilo Braga (participant/ Dynamox)

Partners: Dynamox.

Project images:

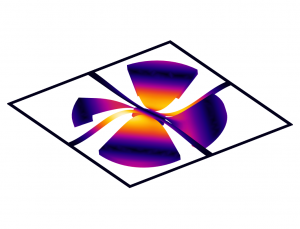

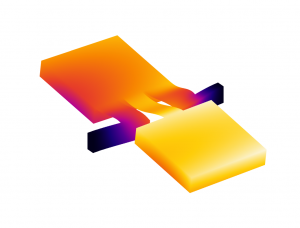

Image 1: Finite element simulations of Energy Harvester MEMS devices. |

Image 2: Finite element simulations of Energy Harvester MEMS devices. |

Image 3: Dynamox’s analysis and prognostic technology is part of industry 4.0’s fourth industrial revolution. |

Image 4: Examples of DynaLogger positioning and illustration of DynaPredict’s fault prediction tools. |

Image 5: Reading temperature and vibration data by the DynaPredict application of sensors installed in the bearing of a crusher. |